Setting the Pace in Lightweight Performance

ABOUT

Anker-Tec – new company, experienced team.

We have been developing and producing machines and components made of carbon fiber composite materials in XXL+ format for over 20 years. By replacing traditional steel structures, we are at least 70% lighter. We achieve high accelerations and speeds, resulting in extreme dynamics in processing large components for areas such as automotive, shipbuilding, aerospace, wind industry, mold making, and wood processing.

Our result: high cost-effectiveness due to shorter processing times, very low energy consumption, and minimal wear.

Max. size: 150m x 10m x 6m

Max. traversing speed: 150m/min

Max. acceleration: 5m/s²

x-Stroke from 5,000mm to 150,000mm (150m),

y-Stroke from 2,000mm to 9,000mm,

z-Stroke from 500mm to 7,000mm

b-Axis +/- 110°, c-Axis +/- 360°

BUSINESS UNITS

Anker ATM

Light, stiff, super-fast for milling, trimming, grinding, laser cutting, ultrasonic processing, waterjet cutting, or bonding.

Anker ACM

Application-specific carbon fiber design for traverses or bridges.

Anker ASW

Anchor Service Workshop. With 2 machines, we process customer orders with our extensive production experience.

MILLING FOR NON METALL WORKPIECES

Anker ATM

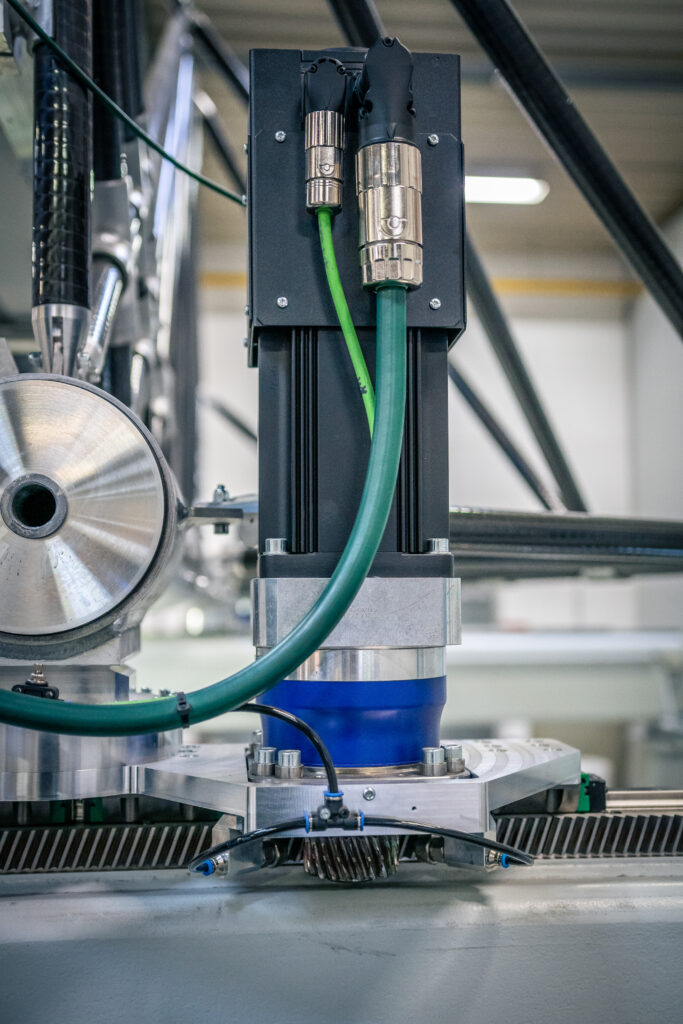

Anker-Tec is a manufacturer of large to very large multifunctional 5-axis machining centers. In addition to the classical milling processing of very large components, the systems can also be used or adapted for processes such as grinding, waterjet cutting, pasting, contour measurement, ultrasonic scanning, and laser cutting.

The machine strokes are freely configurable as standard.

x-Stroke from 5,000mm to 150,000mm (150m),

y-Stroke from 2,000mm to 9,000mm,

z-Stroke from 500mm to 7,000mm

b-Axis +/- 110°, c-Axis +/- 360°

Since the y and z axes are constructed in lightweight design as a carbon fiber-aluminum structure, very low masses are accelerated and moved. This results in technical and economic advantages such as:

Very high dynamics due to high accelerations

Very high traverse speeds

Very low maintenance due to minimal wear of moving parts

Extremely low energy costs

No elaborate foundation required, standard heavy-duty flooring is sufficient

Our machines are developed and built in Germany. We exclusively use components from reputable manufacturers such as Bosch, Siemens, Heidenhain, Rittal, IGUS, etc.

POSITIONING SYSTEMS

Anker ACM

Based on the long-standing experience of the employees at Anker-Tec, we can offer specialized solutions. Our focus is on large lightweight systems for various tasks. We are capable of individually developing large multi-axis systems and designing them to meet specific customer needs using FEM (Finite Element Method). These can be traverse systems made of carbon fiber tubes or systems made from carbon fiber composite panels. The production of the panels takes place in our own panel manufacturing facility.

Examples:

traverse systems for wind tunnels, machine portals y- and Z-axes

Services & Maintenance

Anker ASW

We also offer production service. With a great deal of specialist knowledge of all types of processing related to our machine concept, such as milling services, production of molds for large components, prototype production and related technology in combination with our own machines.

Currently two 5-axis machines are available for customer orders.

Maschine 1

3-axis machining: 9.650mm x 4.000mm x 1.500mm

5-axis machining: 8.450mm x 2.800mm x 1.500mm

Machine 2

3- axis machining: 13.000mm x 4.100mm x 1.900mm

5- axis machining: 11.800mm x 2.900mm x 1.900mm

All non-metallic materials such as pastes, GRP (glass-reinforced plastic), CFRP (carbon-fiber-reinforced plastic), wood, foams, etc., can be processed.

CONTACT

FIll out the form below and we will contact you as soon as possible